Quick Service Request

Send Product Request

About RS Engineering Works

Industrial Spare

Specialists

RS Engineering Works manufactures custom precision machined components for industries in India and abroad. Since 2010, we have specialized in granite and marble machinery spares, multi-wire saw parts, polishing heads, and line polishing components. We also provide reverse engineering solutions. Based in Hosur, we produce high-quality parts in steel, stainless steel, aluminum, brass, and cast iron, ensuring accuracy, durability, and customer satisfaction.

About RS Engineering Works

Industrial Spare

Specialists

RS Engineering Works manufactures custom precision machined components for industries in India and abroad. Since 2010, we have specialized in granite and marble machinery spares, multi-wire saw parts, polishing heads, and line polishing components. We also provide reverse engineering solutions. Based in Hosur, we produce high-quality parts in steel, stainless steel, aluminum, brass, and cast iron, ensuring accuracy, durability, and customer satisfaction.

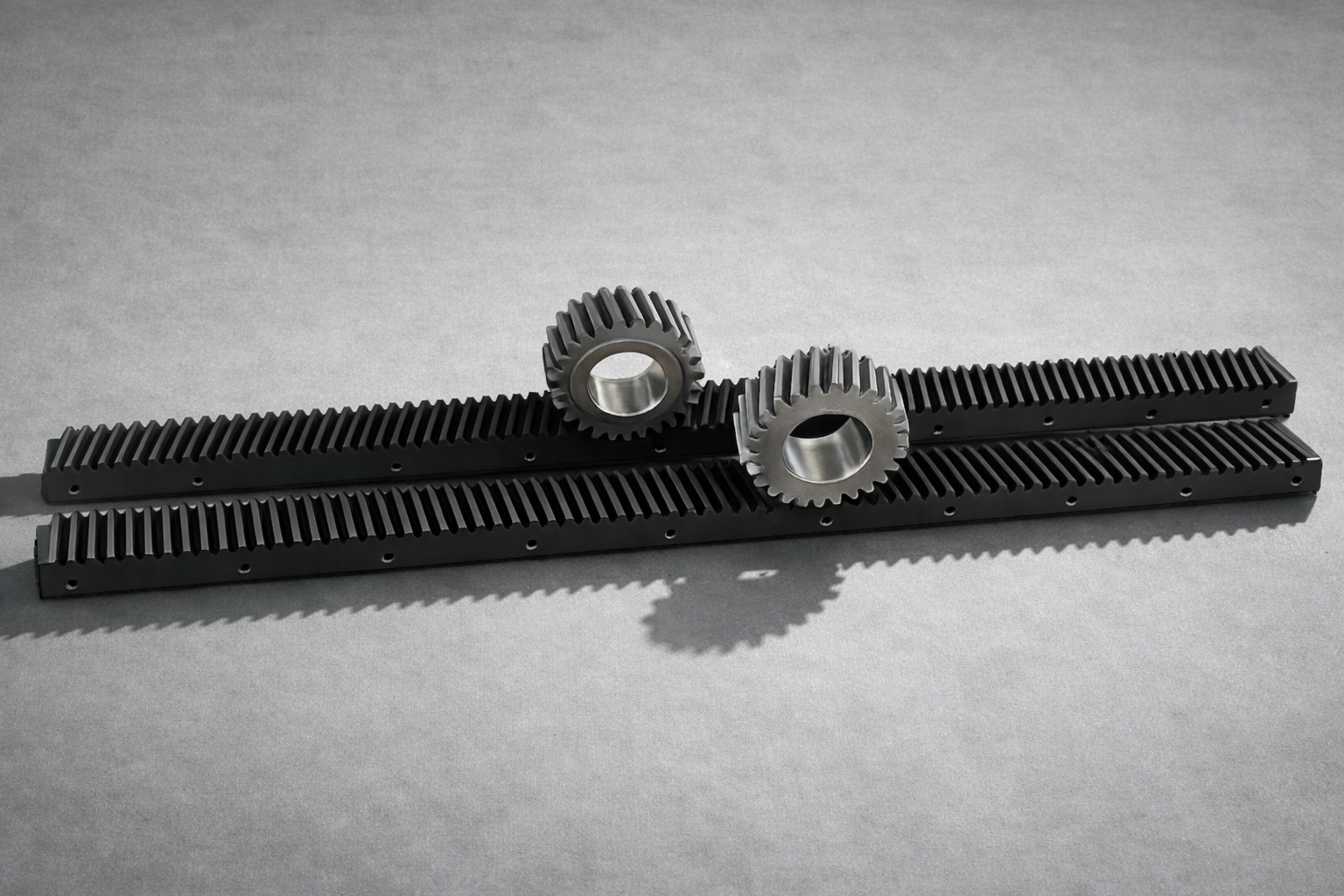

Our Products

We Provide High-Precision Machined Components

WHY CHOOSE US

Choosing RS Engineering Works means trusting a team dedicated to precision, quality, and performance. We focus on delivering reliable components that keep your machinery running strong.

We recreate unavailable or worn-out spares with improved strength and accuracy for better machine life.

With 15+ years in precision machining, we deliver consistent quality trusted by top industries.

Every part is tailored to exact specifications, ensuring the perfect fit for any machinery.

We use advanced processes to achieve high accuracy, superior finish, and long-lasting performance.

Our products are built for durability, and we ensure timely delivery for all small and large orders.